• Pipeline

• Pipeline

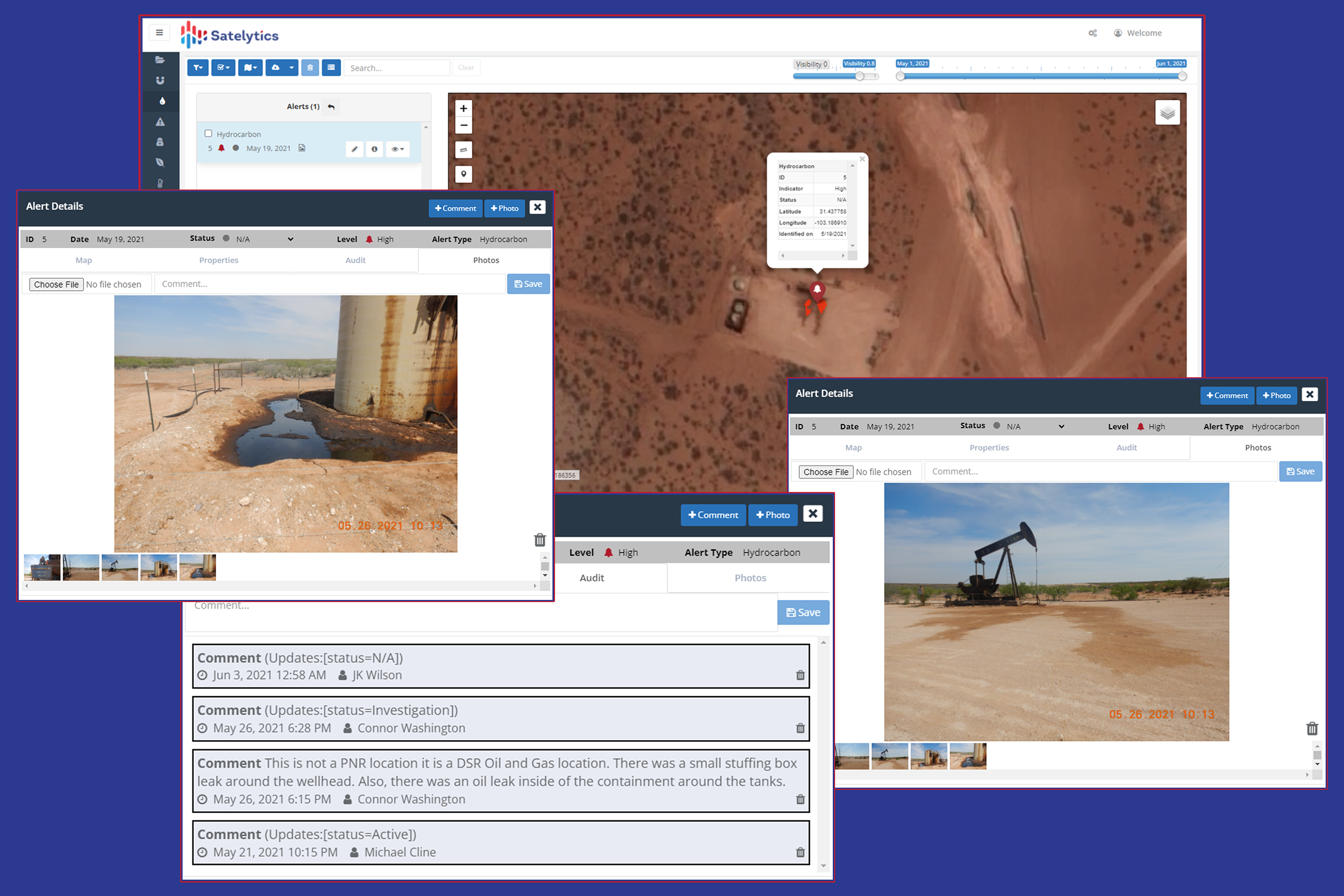

SAFETY. It’s a powerful word in industry. We open meetings with a safety minute. We have safety standdowns to emphasize its importance during the day. We keep tallies of our safety metrics prominently displayed on a big board in the shop or office. For energy infrastructure spread over vast areas, routine monitoring is a safety pain point. Our customers are increasingly harnessing geospatial analytics to improve their safety record.

Most pipeline operators assess “miles driven” as one of their safety metrics. These companies look to reduce this number, as each trip brings additional risk, cost, and emissions. Companies utilize aircraft and helicopters for routine monitoring, which has been a regulatory requirement since the 1950s. Aerial observation can cover larger areas of interest than driving but still relies on a person looking out the window to spot threats. This mode of monitoring is inherently susceptible to weather and mechanical failures. Sadly, we know about the latter from current customers who have experienced a loss of life and now monitor with satellite data instead of putting employees in harm’s way.

Geospatial analytics is an excellent fit for routine monitoring for several reasons:

Send your experts only where needed, not on routine monitoring missions.

Safety pain points exist in any organization. If yours are spread out over large asset areas, Satelytics geospatial analytics can address many of them simultaneously with a single set of data for a single cost.